Panels

Most panels are build the same way. They are made out of 6 mm acrylic and a top layer of 0.5 mm Hesa glass (white). These two layers are melted together with chloroform. This top layer acts as a diffuser for the back lighting.

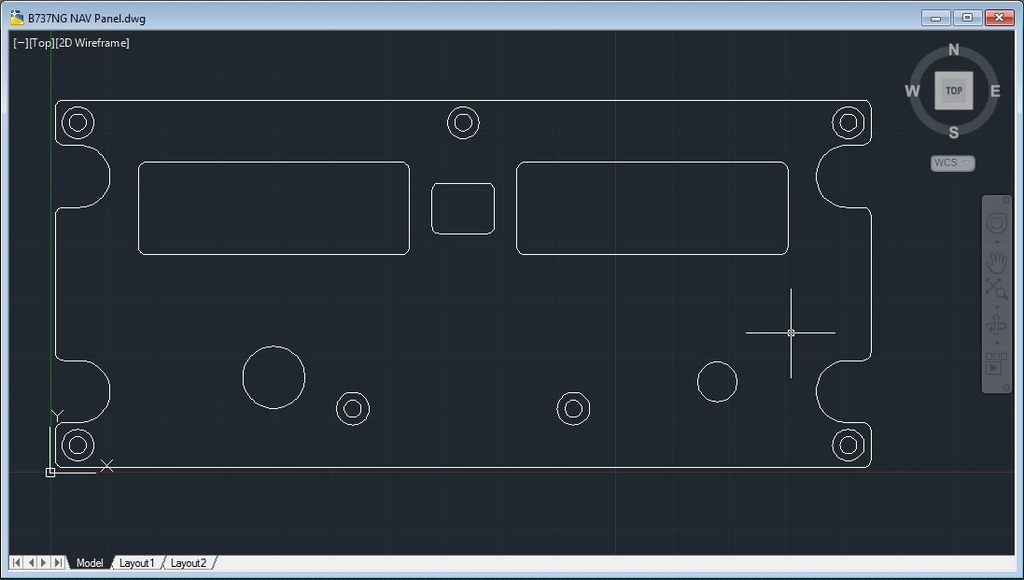

Creating a panel always starts with a CAD drawing. This is done in AutoCAD, the drawing shown below shows a few layers of the NAV panel, which are needed to cut out the panel by milling from the front.

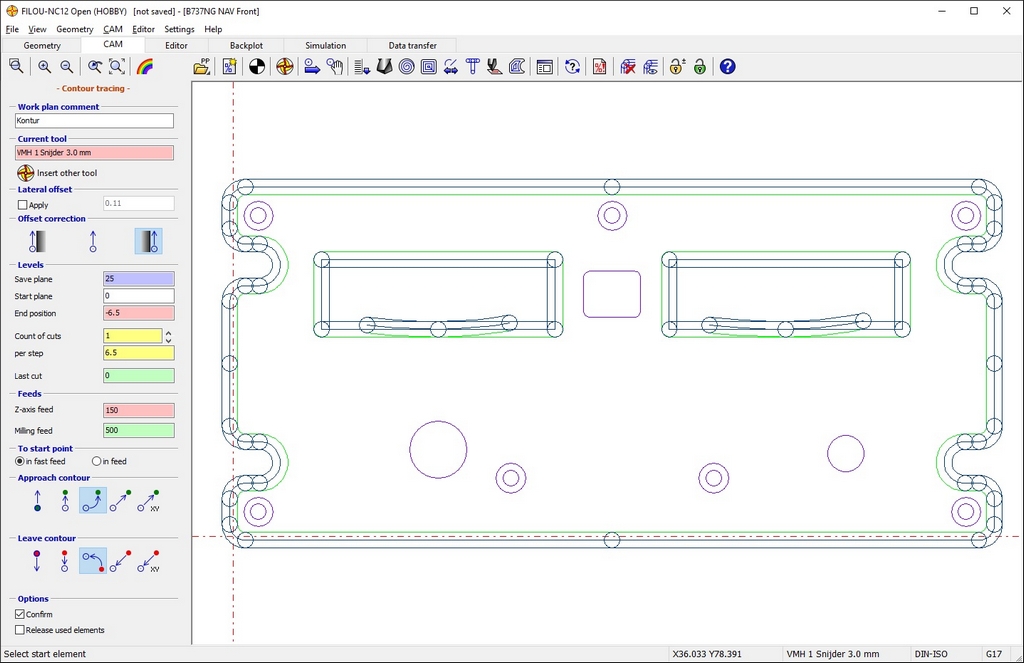

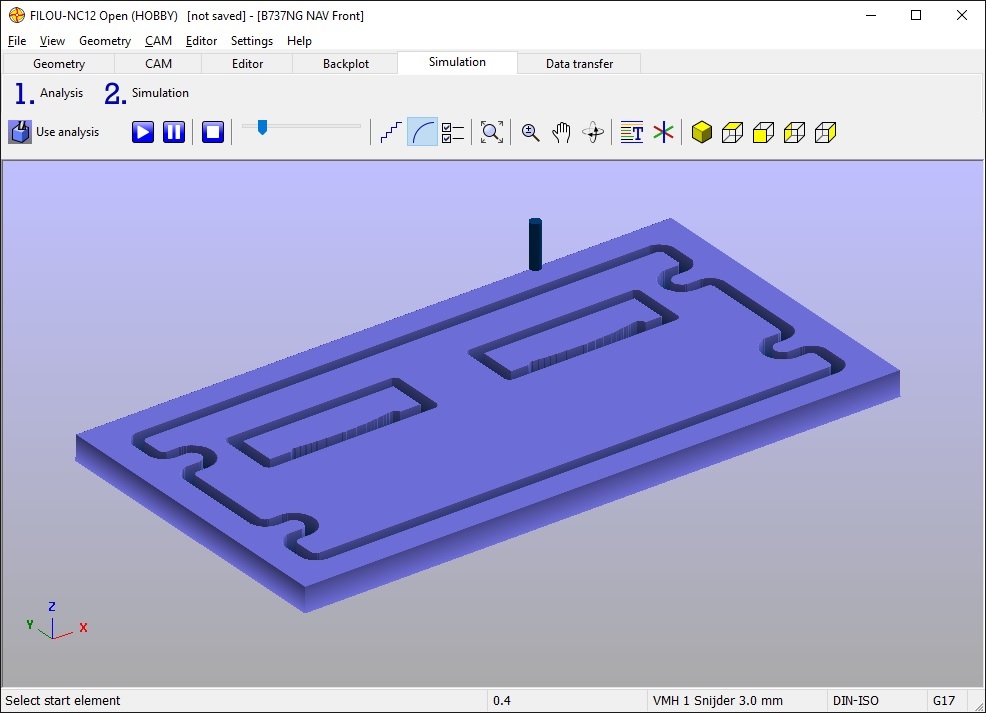

When the CAD drawing is finished it can be imported into the program which will create the G-Code for the CNC milling machine. I'm using Filou for this process.

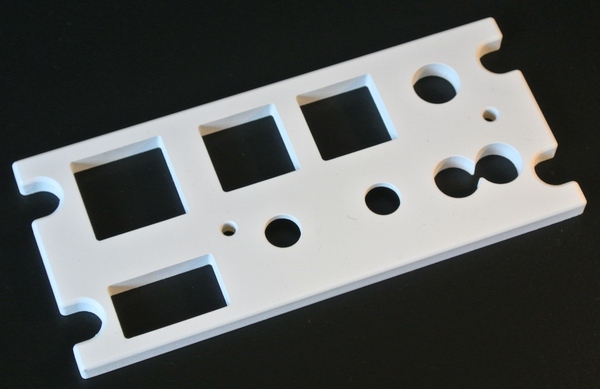

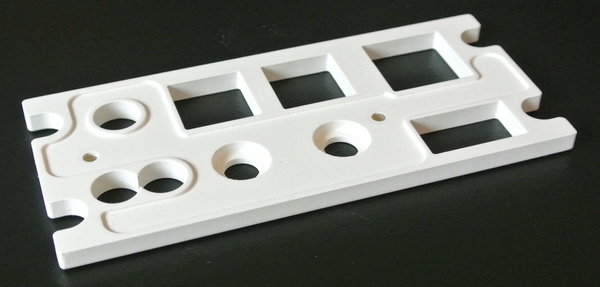

This is the result after the milling process (front and back of the panel). Panel already has white primer applied. WinPC-NC software is used to control my CNC milling machine. This software interprets the G-Code and sends the correct command to the milling machine.

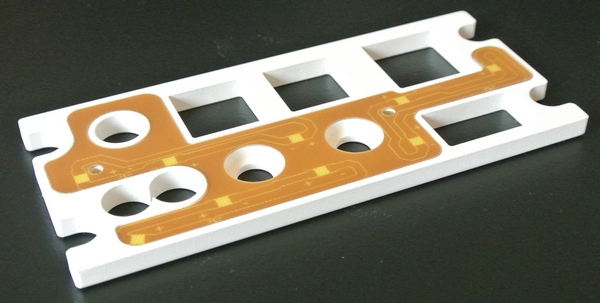

Test fit the PCB for the back lighting of the panel. It will fit exactly in the pocket milled at the back of the panel.

Now the panel can be sprayed in the correct color and after drying the text can be engraved.

I will be adding more pictures of the process in the future, work in progress.